Metal spinning Metal spinning contains a disk or cylinder of sheet metal that is placed onto a mandrel with a lathe along with a roller Device designs the sheet towards the mandrel condition.

Add your CAD design and style or use our pieces builder and have a no cost instantaneous quote on your customized laser Reduce parts, all sent to your doorway within a make any difference of times.

Additionally, you will must know what flange size you’ll have to have and when that duration will do the job in the picked content. (The flange is the sting from the component that’s bent in the stationary base.

If you favor tender and sleek, drapey sheets that resist wrinkling, this set feels deluxe and is particularly a lot better than sets twice the value.

Galvanized steel is usually Reduce with laser chopping, but it's not suggested, because the high heat may result in the protecting coating remaining weakened, together with poisonous zinc-oxide fumes staying produced.

Hydroforming can generate intricate shapes with uniform wall thickness, with diminished squander and relatively cheap in comparison with other forming techniques.

This long lasting material may stand the take a look at of time, Therefore if protection is the highest worry, sheet metal building supplies are definitely the go-to substrate.

Permit’s take a look at a couple of explanation why a Traditional Metal Roof essentially the most eco-friendly roof You should purchase. Understand why metal roofing is eco-friendly

One more essential assets of sheet metal is its power-to-weight ratio. This means that it maintains its strength even though decreased in thickness, enabling for lightweight nonetheless strong styles.

During extend forming, attach the sheet metal to a tensioned equipment and utilize tension to realize the specified form devoid of producing any defects. Deep drawing, On the flip side, pulls the metal right into a die cavity, developing deep, hollow shapes with uniform walls.

This process is generally applied read so as to attain straight edges over a sheet of metal that has uneven or rough edges. This machinery works by using hand electric power, hydraulics, electric power, or pneumatics depending on the thickness of fabric and duration of the Slice desired.

Punching is the process of eradicating substance from sheet metal to build holes, slots, or unique styles. Sheet metal is put amongst a punch in addition to a die. The die supports the sheet metal, although the punch is forced with the sheet metal to the die to produce the outlet or condition.

When determining the gap involving two or even more fasteners, you are able to work out the gap by the components, C/L to edge + 1/two the diameter of the second mounting gap. Instance revealed with x2 of the same components.

Different elements possess one of a kind properties which make them suitable for precise programs, allowing for sheet metal for being a flexible and extensively applied content in several industries.

Angus T. Jones Then & Now!

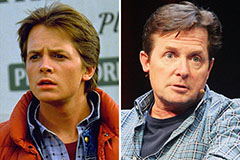

Angus T. Jones Then & Now! Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Christina Ricci Then & Now!

Christina Ricci Then & Now! Jurnee Smollett Then & Now!

Jurnee Smollett Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!